Skid Steer Loader Information

A skid-steer loader is a small, rigid-frame, engine-powered equipment with lift arms that may attach to various buckets and other labor-saving tools or accessories.

In skid-steer loaders, the front and rear wheels on each side are mechanically coupled to turn at the same speed. The left-side drive wheels have autonomous control over the right-side drive wheels. Often, these vehicles have four wheels or tracks. This is accomplished by using two unique and independent transmissions, one for the left-side wheels and one for the right-side wheels. The initial versions of skid steer loaders had both forward and backward clutch drives. Nearly all contemporary skid steers were manufactured with two distinct hydrostatic transmissions starting in the middle of the 1970s (one for the left side and one for the right side).

Without the use of a separate steering mechanism, the wheels are typically fixed in a straight alignment to the machine's body. Due to differential steering, in which the left and right wheel pairs are driven at different speeds, the vehicle rotates by sliding or dragging its fixed-orientation wheels across the ground. Skid-steer loaders are capable of making zero-radius turns by rotating one set of wheels forward while moving the other set of wheels backward. Due to its "zero-turn" function, these machines are incredibly manoeuvrable and useful for applications that demand for a tiny, robust, and agile loader or tool carrier in confined locations (the machine can turn around within its own length).

The machine's exceptionally robust design and strong wheel bearings prevent it from being harmed by the torsional stresses created by this dragging motion. Due to their high ground friction, skid steers can damage supple or fragile road surfaces just like tracked vehicles. They can be altered to have less ground friction by employing wheels that are well-built, like the Mecanum wheel.

"Compact track loaders" are the name given to skid-steer loaders that operate on tracks rather than wheels.

Skid steer loaders, both wheel and track models, function best when they are unbalanced and have either the front or the back wheels heavily loaded. When the bucket is empty, all skid steer loaders are heavier in the back, which causes the back wheels to pivot as the front wheels move. The weight distribution of a bucket alters when it is fully loaded, and the front wheels begin to weigh significantly more than the back wheels. When the vehicle is loaded and making a zero-turn, the front wheels revolve and the back wheels slide.

Unbalanced machinery rotates more slowly and progressively wears down its tyres. Skilled personnel continuously maintain a heavier machine in the front or back. Both sets of wheels resist pivoting or sliding when the weight is evenly distributed between the front and rear axles and is at (or nearly at) 50/50. As a result of the high friction, the machine starts to "buck." In this situation, tyre wear increases significantly.

Unlike a traditional front loader, these machines feature raise arms alongside the driver with pivot points behind the driver's shoulders. Since the operator was so close to moving booms in the early skid loaders, they were less safe than conventional front loaders, especially since there was no rollover protection structure. Skid loaders today have open or fully enclosed cabs, along with other safety features. Like other front loaders, they may move materials from one location to another, transport goods in the bucket, load materials into trucks or trailers, and perform a variety of digging and grading jobs.

The History Of Skid Steer Loaders

The first front-end loader with three wheels was developed in 1957 by two brothers from Rothsay, Minnesota, named Cyril and Louis Keller. The loader was built by the Keller family to help farmer Eddie Velo automate the removal of poultry excrement from his barn. Its name references to the machine's capacity to turn around within itself while doing tasks that a typical front-end loader would perform.

The Melroe brothers of Gwinner, North Dakota's Melroe Manufacturing Company hired the Keller family to continue perfecting their invention in 1958 after purchasing the patent rights to the Keller loader. By the end of 1958, the product of their collaboration was the M-200 Melroe self-propelled loader. It had two independent front-drive wheels, a rear caster wheel, a 12.9 horsepower (9.6 kW) engine, and a 750-pound lifting capability (340 kg). Two years after the caster wheel was switched out for a rear axle, the first real four-wheel skid-steer loader, the M-400, was made available. The 1,100 pound rated operating weight of the M-440 is propelled by its 15.5 horsepower (11.6 kW) engine (500 kg). Skid-steer development continued with the M600 loader into the middle of the 1960s. Melroe registered the trademark for the recognisable Bobcat brand in 1962.

Cyril and Louis Keller, two brothers from Rothsay, Minnesota, created the first front-end loader with three wheels in 1957. The Keller family constructed the loader to aid farmer Eddie Velo in automating the clearing of bird droppings from his barn. Its name alludes to the machine's ability to pivot internally while carrying out duties that a traditional front-end loader would carry out.

After acquiring the Keller loader's patent rights in 1958, the Melroe brothers of Gwinner, North Dakota's Melroe Manufacturing Company engaged the Keller family to continue developing their innovation. The M-200 Melroe self-propelled loader was the result of their partnership by the end of 1958. It possessed a 12.9 horsepower (9.6 kW) engine, two independent front-drive wheels, a rear caster wheel, and a lifting capacity of 750 pounds (340 kg). The first genuine four-wheel skid-steer loader, the M-400, became available two years after the caster wheel was replaced with a rear axle. The M-440's 15.5 horsepower (11.6 kW) engine propels its 1,100 pound rated operating weight (500 kg). With the M600 loader, skid-steer development lasted through the middle of the 1960s. In 1962, Melroe filed for trademark protection for the recognisable Bobcat name.

Skid Steer Loader Applications

Occasionally, a skid-steer loader can replace a large excavator by digging a hole from the inside. Particularly when installing swimming pools in backyards too small for a large digger The skid loader first makes its way to the target excavation's perimeter and builds a ramp there. After that, it uses the ramp to carry material out of the hole. As the depth of the excavation increases, the skid loader lengthens and steepens the ramp. This method can also be used if there isn't enough overhead clearance for a large excavator boom yet you want to build a basement underneath an existing house. Several companies produce backhoe attachments for skid steers. These can be applied in the same circumstances and are more effective for excavating in a short space than the technique previously mentioned.

Pallet forks or buckets can also be used to transport raw materials around a construction site. Tough terrain forklifts have very low manoeuvrability while rough terrain forklifts are smaller, have great movement, but poor traction. Skid steer loaders are very manoeuvrable and have outstanding traction even though they typically have a lower lift capability than forklifts.

Skid steer loaders are a fantastic alternative when larger snow ploughs struggle to manoeuvre past existing vehicles, lampposts, and curbs in confined parking spaces. Skid steers may remove snow in addition to ploughing and pushing it into a mound.

Applications For Small Frame Loaders

If you work in the trenching, levelling, post hole digging, small demolition, material transfer, building, and site development industries, you should investigate compact skid steers. Due to their small size and high regard for mobility, they are ideal for any activity where space can be at a premium. Landscapers can avoid the most fragile terrain and injure an established grass the least by employing their low weight.

Applications for Medium Frame Loaders

Because they are ideal for projects that call for precision movement, the best skid steers have a medium frame. Any construction or material management site can benefit from their expertise in cleaning debris, transporting large objects, light grading and levelling, and site preparation. They are powerful enough to complete all but the most challenging tasks at major building sites, even if they need a bit more room to operate than smaller ones.

Applicationsfor Large Frame Loaders

Despite being more powerful and capable of using the complete range of attachments than their smaller counterparts, large frame skid steers provide quick movement and a low profile, allowing them to manoeuvre through construction sites without being impeded by larger equipment. The effectiveness of these models is advantageous for large-scale excavation projects, drilling operations, considerable demolition projects, and grading operations. With the aid of attachments, large frame skid steers can move and dump vast quantities of material as well as carry out almost any other task you would encounter on a building or demolition site.

Clearing Snow

A skid steer's bucket can clear snow from a road or construction site fast, but in colder climates, operators may choose to use a snow blade or snow blower attachment.

Excavation

A skid steer may perform excavation tasks because of the addition of tools such a ripper, trencher, tiller, or wheel saw.

Construction

An asphalt miller or a cement mixer can be added to a skid steer to speed up operations on construction and building projects.

Landscaping Works

Due to its stump grinder, wood chipper, tree spade, and trench-digging attachments, a skid steer is an excellent equipment for landscaping work, whereas pallet forks and bale spears are more suited for agricultural and warehousing tasks.

Trenching and Digging

The common digging tools that skid steers offer are trench diggers, backhoes, and augers (which operates like a corkscrew to dig a precise hole).

With the right attachment, your skid steer is the best choice for any task on almost any construction site. Therefore, teams must educate skid steer operators about the necessary safety and upkeep for the skid steer and any accessories used on each project.

Different Types Of Skid Steer Loaders

Wheeled and tracked skid steer loaders are the two primary varieties. You can learn more about these different loader types, their sizes, and their capabilities in the articles listed below.

Wheeled Skid Steer Loaders

Skid steers were exclusively available as wheeled variants before track steers were created to alleviate some of their shortcomings. Each of them has advantages and disadvantages.

Benefits

Wheeled skid steers work best on flat terrain like asphalt, concrete, or compacted soil. Due to their ability to traverse these surfaces far more quickly than tracked skid steers can, they can cover more ground more quickly.

Wheeled skid steers are often favoured on landscaped grounds where tracked skid steers could rip up surfaces.

They are less expensive both to buy and to maintain than track steers.

Disadvantages

A wheeled skid steer can sink in mud since it only has four points of contact (its tyres) to support its weight. A rough surface could cause a tyre to blow out.

The lifespan of tracks is greater than that of tyres.

Tracked Skid Steer Loaders

Tracked skid steers can withstand higher weight since they have two wide tracks. Skid steer tracks have the following advantages and disadvantages when compared to tyres:

Advantages

Because of its greater weight distribution and lower weight transfer to the ground, they perform best on wet, muddy, snowy, and loose sand and gravel terrain. Skid steers with tracks float over soft ground as opposed to sinking into it.

Due to their increased ground contact and lower centre of gravity, they are more stable on slopes.

Track-equipped skid steers are more pleasant to ride than ones with wheels. They can break through soft ground and do not compact the earth. They also have a stronger lifting force.

Disadvantages

Before using a track steer on concrete or asphalt, you must stop. According to Hill, the track's aggressivity "may rip up that type of surface."

Remember that tracked skid steers need more maintenance and cleaning than wheeled skid steers when determining whether to buy a skid steer rather than rent one. They also cost more money.

More labour is needed to change the track than to replace the tyres.

Skid Steer Loader Sizes

Classification

Skid steer loaders fall into three categories based on how well they perform:

50 horsepower and under 1,750 pounds packed into a small frame

a medium-sized frame with a 1,750–2,200 pound weight and 50–70 horsepower.

Over 70 horsepower, 2,200 pounds, and a sturdy structure

In order to select the model that is appropriate for you, you must be aware of the capacity needs for both your workload and your workspace. Despite the fact that unfinished or uneven work areas may require the use of larger, more powerful equipment, smaller machines are nevertheless easier to manoeuvre in small spaces.

If your work is large, you will need a good skid steer with lots of power. For a long material discharge channel, faster equipment might be more useful. You'll obviously want to be sure your loader can handle the size of attachments you desire in order to avoid overtaxing it.

Guide To Skid Steer Loader Attachments

As you might be aware, a skid steer, often referred to as a skid steer loader, is a device having essentially limitless uses. The little, rigid-framed, engine-powered workhorse has a name that fits because of its steering system. The wheels merely slow down on either side to produce a "slide," which is more akin to the machine dragging its feet to aid spin, rather than changing direction to steer. Given that Bobcat is the most well-known manufacturer, you may have heard these referred to as Bobcats.

By looking through the various skid steer accessories for a skid steer loader that are offered on our skid steer attachments page, you can utilise the same equipment to carry out a range of tasks. This increases their tremendous value. But there is still a lot to learn about these attachments.

What Is A Skid Steer Loader Attachment?

The most popular excavator attachment is a bucket. They are perfect for scooping and excavating because to their steel construction and teeth-like edges. The buckets used for grading and ditching stones, commonly referred to as "ditching buckets," are the most popular (the trenching bucket). It's vital to consider the quality of the soil and any prospective attachments, such as couplers, when choosing the sort of bucket to buy or rent.

Can A Skid Steer Loader Be Attached To Any Skid Steer Loader?

While certain skid steer attachments are incompatible with others, most of the necessary accessories can be mounted on your skid steer. This is because there are different types of skid steers, each with a special aptitude and set of attributes. Therefore, some attachments could be too much for your specific skid steer to handle. You should get in touch with the makers of each component to find out if your skid steer and its accessories will work together.

Because the attachment platform was designed to be "universal," and there are adaptors to emphasise this, the majority of skid steers can mount the majority of attachments, but this does not guarantee that they will work together. Productivity may be affected or a dangerous working environment may result from an attachment's incompatibility with a skid steer. As we discuss in more detail below, you should also consider if your attachments require low flow or high flow capacity.

Coupling An Attachment To A Skid Steer Loader

A skid steer attachment's coupling process is obviously crucial, however due to the "universal" platform that skid steers employ, coupling is often easy and uniform for the majority of attachments. Here are some quick skid steer attachment connection examples:

dispense with any existing attachments

For Hydro-mechanical

Release any system pressure that has built up in the auxiliary lines for machines that have "connect under pressure" coupling. The coupler should then be moved in the direction of the machine and held in position for five seconds. Consult your attachment's owner's handbook whether this is necessary.

After removing the lines from the hose guide, couple them. In other words, this lessens the chance of contamination and the amount of pressure that accumulates prior to the next use. To remove the attachment itself, adhere to the steps stated below.

Uncoupling The Attachment

By depressing a button in the cab or manually releasing a lever behind the attachment, the connection pins can be automatically disengaged from motorised coupling devices.

Once the top of the connection assembly is free of the angled work plate, it should be progressively backed up.

You can now securely and precisely detach the attachment you don't need before coupling the attachment you do need by following the instructions below:

Coupling The Attachments

Move the attachment gently in the direction of the angle of the coupling assembly to align the work plate.

The coupler needs to be raised and pointed in the direction of the skid steer.

In order to orient the coupler toward the skid steer, it must be lifted.

You can verify that the coupling assembly is secure by fully lowering the attachment and dragging it along the ground in the opposite direction.

Before raising the tool once more, carefully inspect it for any movement and make sure the pins are still engaged. Check the owner's manual for your attachment to see if there are any specific instructions for attaching.

If your attachment uses hydraulic power, you must connect it after completing the prior stages. As can be seen above, the auxiliary connectors on the machine are connected to the hydraulic lines from the attachments.

Starting with three points of contact, carefully exit the apparatus.

Cleaning the connector is the next step, after which the normal flow lines should be fed through the hose guide on the left lift arm. For instructions on how to route your attachment properly, always consult your owner's manual.

If your machine features "connect under pressure" connections, you must first release the pressure before you can ultimately connect the hydraulic lines to it. Push the coupler on the machine and connector on the work tool into one another and hold for five seconds to complete this.

What Skid Steer Attachments Are There?

This useful, multipurpose tool is probably already installed on a lot of skid steer loaders. The best part about them is that some of them have a special "four-in-one" design with an opening bucket that can be used for digging, pushing loose debris, and transferring items that have been hauled back (with the bucket open).

Skid Steer Loader Breaker

Materials are typically torn apart with the breaker attachment, a more specialised tool that performs comparable duties as a jackhammer. Road construction, demolition, and maintenance are all done with this hydraulic "hammer."

Skid Steer Loader Fork

Your skid steer can be successfully used as a temporary forklift to move heavy loads of stuff on pallets with the help of the fork attachment (most commonly).

Skid Steer Loader Grapple Bucket

The tines on this attachment, which is utilised in many different industries, make it simpler to handle bulkier and more challenging objects like logs. The bucket of this attachment is used for scooping and storing items (like a freestanding bucket).

Skid Steer Loader Planer

When cutting and milling concrete, the planer routinely chips away at the sub-base, and it can even recycle the waste right away.

Skid Steer Loader Spreader

A spreader, as the name suggests, is an attachment that spreads granular materials including seed, sand, fertiliser, and salt. During the winter, these are mostly used to spray salt to help in snow removal.

Skid Steer Loader Auger

An auger is a helpful addition if a skid steer is required to drill substantial holes in the ground, such as those required for erecting poles or trees. They are hydraulic and offered in a range of widths to suit your requirements.

Skid Steer Loader Steel Tracks

Steel tracks are great for improving the control and traction of your skid steer across unlevel terrain like sand, stones, and mud. The tyres that were originally mounted on your skid steer are not compatible with these; please be aware of this.

Log Grinder

A skid steer operator may typically utilise a log grinder at a 90-degree angle to remove tree stumps and logs for resizing.

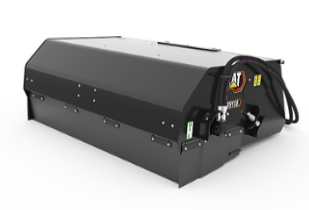

Sweeper

Unquestionably, a sweeper is the attachment that works best for sweeping, cleaning, and collecting trash both forward and backward. A gutter brush is frequently a choice for increased adjustability and efficiency.

Flail cutter

The ideal attachment for pruning tiny trees and sparse vegetation is a flail cutter. Because of their floating linkage, which makes it easy for them to follow the ground, they are great for efficiently eradicating undesirable plants, especially in small places.

Bobcat Skid Steer Loaders We Supply

Robs Digger Hire Oxfordshire Copyright© 2022 All Rights Reserved